ABBA LINEAR TECH CO., LTD.

BR linear guide - Top solution for harsh environments and cost controll

Current industry faces numerous challenges, including the need for equipment to operate reliably under increasingly demanding environmental conditions set by end customers. At the same time, enterprises must manage internal cost controls to adapt to market changes, contend with a highly competitive market environment, and maintain product competitiveness and sustainability. In this context, ABBA BR linear guides stand out as the preferred choice across various industries due to their exceptional performance and high cost-effectiveness.

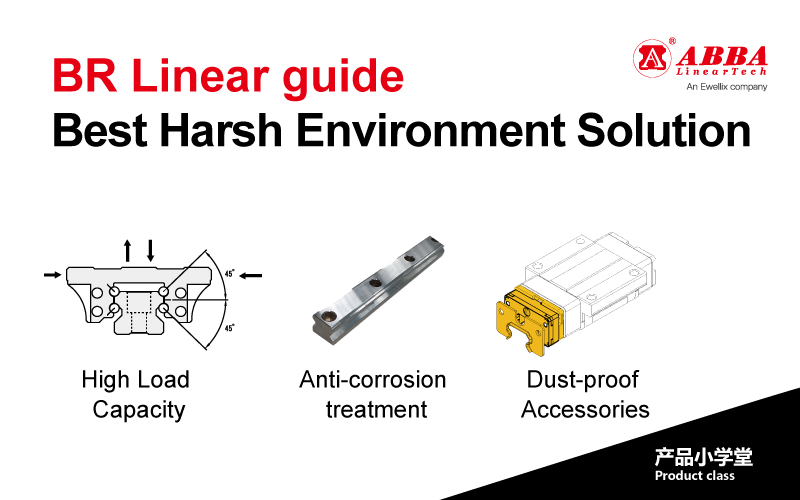

Application benefits in Harsh Environments

▸ High-load capability

High-Rigidity for X-arrangement Four-Row ball design: The 45-degree contact angle between the steel balls and the ball raceway ensures equal load-carrying capacity in all four load directions. This design offers higher flexibility, effectively absorbing parallelism and height errors between multi-axis systems, resulting in smoother and more stable operation.

▸Corrosion-Resistant Treatment

Trivalent Chromium Surface Treatment: Suitable for high-humidity environments (such as indoor automation equipment), this treatment helps prevent corrosion, meets aesthetic requirements, and is ideal for long-term storage of unopened rails.

▸Excellent Dust-Proof Accessories

• Low friction shield: Suitable for environments requiring low operating resistance and free from external contaminants, such as clean rooms.

• Scraper plate: Suitable for environments with high levels of contaminants or metal shavings, such as milling machines, to prevent damage to dust-proof covers from large contaminants or metal debris.

• U type metal frame + side seals: Suitable for environments where dust may infiltrate from beneath the block.**

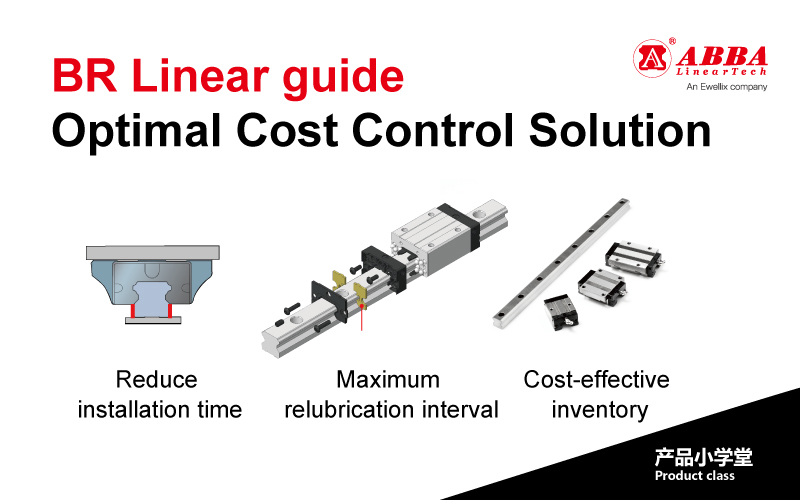

Application benefits under strict cost control

▸ Reduce installation time

Both sides of the rail can serve as reference surfaces, making installation convenient and fast. This shortens time-to-market, eliminates concerns about incorrect installation, and maintains consistent assembly precision for customers.

▸Extend Lubrication Intervals

The standard model features a self-lubricating system. For standard BR models with sizes up to 30, they include self-lubricating system, eliminating the need for lubrication channel and equipment, which significantly reduces lubrication costs. Additionally, an optional self-lubrication system is available. This system uses a high-oil-content reservoir and optimized oil film formation design to provide ample and precise lubrication to the raceway, achieving both environmental benefits and extended lubrication intervals.

▸Cost-effective inventory

Compliant with ISO 12090-1 standards, ensuring dimensional interchangeability with all brands adhering to ISO standards. The rails are compatible with all types of blocks of the same size.

Applicable industries for BR Linear Guides

•Automation Equipment:Robots and conveyor systems require high precision and reliability

• Machine Tools:Milling machines and lathes, excel in high-speed and high-precision environments.

• Electronics Manufacturing:Requires precision assembly equipment in dust-free environments.

• Packaging and Printing Equipment:Needs fast, smooth movement and high durability.

• Medical Equipment:Surgical robots and imaging devices require high cleanliness and precise control.

ABBA BR linear guides not only excel in performance and cost control but also actively respond to global sustainability trends. Their self-lubrication system reduces lubrication oil usage, minimizing environmental impact and meeting modern industrial demands for environmental protection and resource conservation. The trivalent chromium surface treatment also extends the rail's service life and reduces maintenance frequency. Through its eco-friendly design, ABBA BR linear guides are committed to providing customers with efficient, reliable, and sustainable green solutions, facilitating the acceleration of automation in the manufacturing industry.

▸Watch the latest video to see how BR linear guides can help you reduce costs.