ABBA LINEAR TECH CO., LTD.

Revolutionizing Electronics: How ABBA Miniature Linear Guides Enhance Automated Optical Inspection

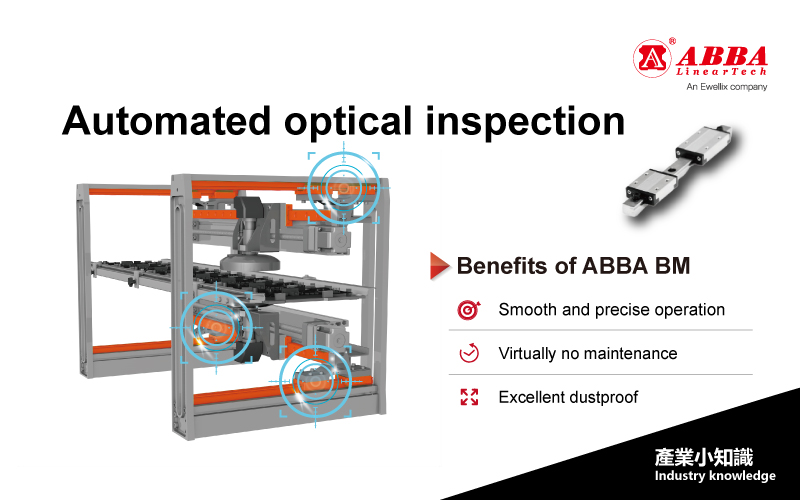

The optical image inspection system primarily utilizes machine vision for inspection, improving upon the traditional method of manual inspection with optical instruments. To accurately capture the surface condition of finished products, the inspection head must move smoothly to precisely obtain all surface information. The innovative ball retention system of the ABBA BM miniature linear guide allows for stable operation of the inspection head, and its maintenance-free feature enhances the productivity of optical inspection equipment, meeting the rapidly increasing demand for chip inspection in industries such as electric vehicles and 5G.

3 advantages of ABBA BR linear guides in Automated Optical Inspection application

▸ smooth and precise operation

BM miniature linear guide features a ball retention system design and optimized ball circulation, ensuring smooth and seamless operation. This design effectively reduces friction and noise, significantly enhancing the dynamic performance and processing quality of optical inspection. The stability and precision of the inspection process are greatly improved, ensuring the reliability and consistency of results.

▸Up to 20,000 km maintenance-free

BM miniature linear guide is pre-lubricated at the factory and equipped with self-lubricating oil pads, ensuring long-lasting and stable lubrication conditions. This feature allows the BM linear guide to maintain a maintenance-free state for up to 20,000 km of operation, significantly reducing maintenance costs and downtime. For the optical inspection industry, this greatly minimizes production downtime due to maintenance, thereby enhancing overall operational efficiency.

▸Excellent dust protection

BM miniature linear guide is equipped with a high-efficiency sealing device that effectively prevents dust and impurities from entering the system. This superior dust protection extends the lifespan of the guide and maintains high-performance operation in harsh inspection environments, ensuring the accuracy of inspection results and the durability of the equipment.

Automated Optical Inspection (AOI) is a high-speed, high-precision system utilizing machine vision for inspection. Dual-camera systems, adjustable via miniature linear guides, inspect both sides of circuit boards on a conveyor, capturing surface conditions and detecting defects using computer image processing. This non-contact method allows for in-process inspection of semi-finished products. AOI is applicable in high-tech R&D, quality control, defense, consumer products, healthcare, environmental protection, and power industries.

常見的微型線性滑軌的光學檢測設備類型

① Printed circuit board (PCB) inspection

• Automated Optical Inspection Equipment (AOI)

• Automated X-ray Inspection Equipment (AXI)

• Coordinate Measuring Machine (CMM)

• Laser scanning microscope

The accuracy of printed circuit boards (PCBs) is crucial for electronic products. AOI and AXI equipment can quickly and accurately detect PCB defects such as soldering defects and open circuits. CMMs and laser scanning microscopes provide high-resolution detection, ensuring board quality and consistency, and reducing rework costs. These technologies are well-suited for high-volume production environments.

② Medical Drug Testing :

• Microscope inspection system

• Pharmaceutical X-ray inspection system

• High-resolution spectrometer

In optical inspection of medical drugs, microscope inspection systems and pharmaceutical X-ray inspection systems provide high precision and sensitivity for analyzing trace impurities and particles in medications. High-resolution spectrometers enable rapid and accurate analysis of drug components, ensuring purity and quality. These technologies facilitate real-time monitoring during production, reducing human error and complying with stringent medical regulations to ensure drug safety and efficacy.。

③ Automotive Industry :

• Coordinate Measuring Machine(CMM)

• 3D optical profilometer

• Laser scanning measurement detection system

• Photographic inspection system

In the automotive industry, coordinate measuring machines (CMMs), 3D optical profilometers, and laser scanning measurement detection systems are used to accurately measure car body dimensions and shapes. These systems also detect defects in complex parts, thereby enhancing production quality and reliability. Photographic inspection systems provide real-time data and automate detection processes, reducing manual intervention and optimizing finished product quality.

④ Space exploration :

• Medium-resolution imaging spectrometer

• Optical telescope

• Optical cameras and analytical instruments on the rover

In space exploration, a medium-resolution imaging spectrometer provides high-resolution images and data for observing and analyzing celestial bodies. Optical telescopes and optical cameras with analytical instruments on rovers capture faint light signals, operating reliably in harsh space environments. They enable remote operation and automated data processing, offering detailed astronomical observation data that advances astronomy and space research.

Automatic Optical Inspection (AOI) systems utilize optical technology to non-contactly inspect electronic components, ensuring accurate and rapid identification of defects and verification of manufacturing precision. This improves product quality and output while reducing waste and costs. By the end of 2036, the AOI market is expected to exceed $2.68 billion USD, with the Asia-Pacific region projected to hold the largest market share of 32%, driven by PCB and electronics manufacturing industries. Increased disposable incomes in countries like China and India will boost demand for automotive and consumer electronics, especially smartphones and other smaller, faster, and more compact electronic products, further stimulating the expansion of the high-quality electronic components market.

In this context, ABBA BM miniature linear guide, with its compact sizes (7/9/12/15), has become an indispensable component in AOI equipment. Its superior stability and precision characteristics play a crucial role in miniaturizing and precisely transferring inspection equipment. The BM series ensures that AOI systems maintain smooth operation at high speed and high precision, significantly enhancing detection performance and equipment reliability. This meets the electronics industry's demand for high-precision and efficient inspection equipment. With continued market growth, ABBA's miniature linear guides will continue to drive advancements in electronic product quality and production efficiency, thereby serving as a powerful force in the development of the AOI market.

▸Watch the Latest Video: Boosting Core Competitiveness in Electronic Products!