ABBA LINEAR TECH CO., LTD.

ABBA linear motion components drive precision upgrades in Machine tools!

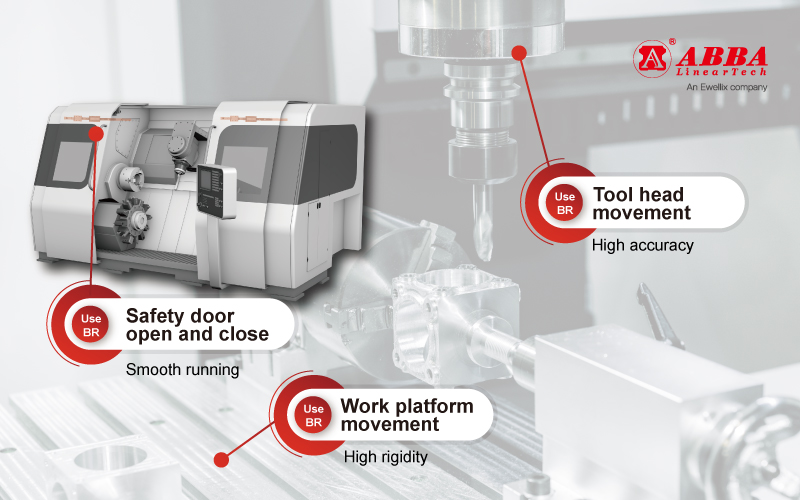

Machine tools are important equipment in the manufacturing process of mechanical parts. They use cutting or grinding methods to shape, size, and achieve surface precision of workpieces. Within these Machine tool equipment, tasks such as tool head movement, safety door opening and closing, and movement of the work platform all require the assistance of ABBA linear guides. These guides are indispensable automation key components in the Machine tool industry.

3 advantages of ABBA BR linear guides in Large Machine tool applications

▸ High rigidity

ABBA BR linear guide adopts high-strength materials and an optimized X-arrangement design structure, capable of withstanding larger loads and impact forces. During the movement of the work platform, the high rigidity of the linear guide ensures stable operation even under high-speed and high-load conditions, reducing vibration and deviation, thus ensuring the stability and durability of the system.

▸High accuracy

ABBA BR linear guide possesses excellent machining precision and installation accuracy. In tool head movement applications, the high accuracy of the linear guide ensures precise positioning and repeatability of the tool head, thereby enhancing machining quality and reducing errors and defect rates.

▸Smooth running

ABBA BR linear guide features an optimized ball circulation contact design and a high-quality lubrication system, reducing friction and ensuring smooth operation of the guide during the opening and closing of safety doors. This minimizes jamming, enhances equipment reliability, and prolongs its lifespan.

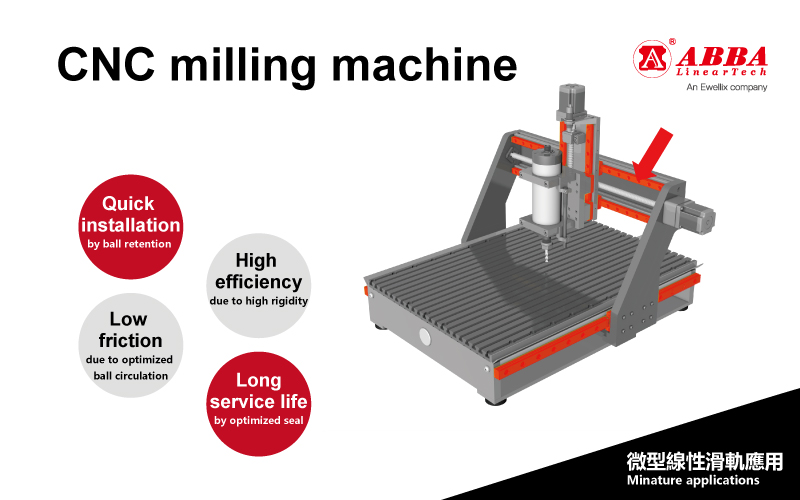

4 advantages of ABBA BM miniature linear guides in Small Machine tool applications

In the realm of CNC machine tools, small three-axis CNC milling machines widely adopt miniature-linear guides for tool head movement. Their strong adaptability and excellent flexibility make them ideal for part processing, enabling precise movements. They are particularly suitable for machining components with highly complex contours or challenging size control requirements.

▸ Quick and Safe assembly

ABBA BM miniature linear guide adopts a ball retention design, making the installation process simpler and quicker. The ball retention effectively prevents the loss of steel balls, simplifies the installation steps, and enhances installation efficiency.

▸Smooth running

BM utilizes an optimized steel ball circulation design to ensure smooth operation, reduce friction and noise, and enhance the dynamic performance and machining quality of the Machine tool.

▸Excellent dustproof

BM is equipped with high-efficiency sealing devices to prevent dust and impurities from entering the linear guide system. Its outstanding dust-proof performance extends the service life of the rail, maintaining operational stability and precision.

▸Low maintenance cost

To achieve optimal maintenance-free operation, all BM blocks are factory pre-lubricated and equipped with self-lubrication system to ensure lubrication conditions within the system. The BM miniature linear guides can maintain a maintenance-free state for up to 20,000 km of operation, reducing maintenance costs and downtime, and improving the production efficiency of the Machine tool.

Common machine tool types and processing instructions

① Drilling : Drilling is a process of creating a circular hole in a workpiece by means of a rotating drill bit. The main equipment used is a drilling machine.

• Application: Mechanical parts, construction, installation of electronic components, etc.。

• Tools: Drill press, electric drill, drill bit.

• Materials: metal, wood, plastic, etc.。

② Milling : Milling is a process of removing material from the workpiece surface by rotating a multi-edged milling cutter. The main equipment is a milling machine./strong>

• Application: parts processing, mold manufacturing, automotive industry, etc.

• Tools: Milling machine, milling cutter, CNC milling machine

• Materials: metal (steel, aluminum, copper, etc.), wood, plastic, etc.

③ Grinding : Grinding is the process of using abrasive tools to finish the surface of a workpiece. The main equipment is a grinder.

• Application: machining of high-precision parts, tool grinding, surface polishing, etc.

• Tools: grinder, grinding wheel, grinding paste

• Materials: carbide, ceramic, glass, metal, etc./strong>

④ Turning :Turning is a process that involves removing material by rotating the workpiece. The main equipment used is a lathe.。

• Application: Processing of shaft parts, disc parts, and tube parts.

• Tools: Lathe, turning tool, CNC lathe

• Materials: metal (steel, aluminum, copper, etc.), wood, plastic, etc.

⑤ EDM : EDM is a precision machining method that uses the electrolytic etching effect to remove materials. The main equipment is the EDM machine.

• Application: Processing of carbide, molds, special-shaped holes and narrow slits.

• Tools: EDM machine, electrodes (usually copper or graphite).

• Materials: Conductive materials, such as cemented carbide, die steel, titanium alloy, etc.

As Generative AI continues to advance, the landscape of Machine tool manufacturing is undergoing a profound technological revolution. Generative AI empowers the automatic generation of diverse code and procedures, facilitating the development of Machine tools with unprecedented flexibility. Moreover, it enables control systems capable of real-time adjustments to operational conditions. In concert with ABBA linear guides, which play a pivotal role in practical machine tool transfer applications, they shoulder essential responsibilities in mechanical motion. The exceptional stability, precision, and reliability offered by ABBA linear guides have become indispensable in elevating the processing quality and efficiency of Machine tools. Their contribution to the advancement of machine tools within the realm of mechanical processing cannot be overstated.

▸Experience precision redefined in the latest video, as cutting-edge technology drives the evolution of Machine tools to new heights! !