ABBA LINEAR TECH CO., LTD.

ABBA BM Miniature linear guide - Unlock high-speed precision instantly

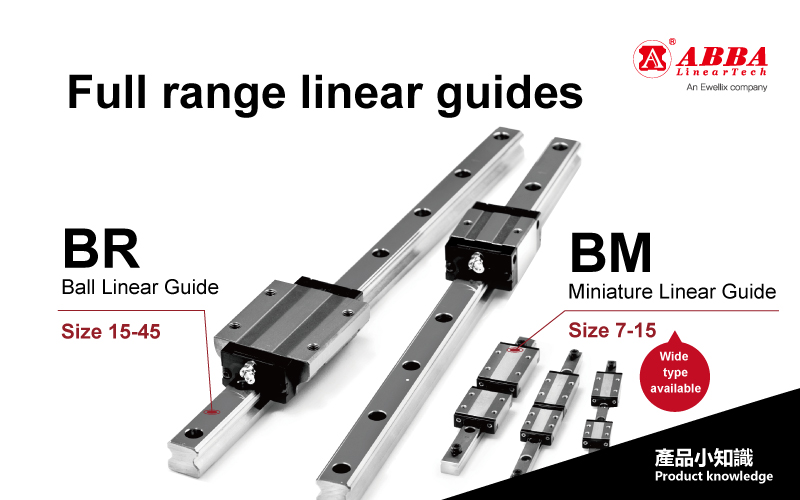

ABBA Linear Tech, with 25 years of manufacturing experience, is a linear guide manufacturer. In addition to offering standard BR linear guides, ABBA has developed the BM miniature linear guide to meet the demands of small precision equipment.

BM miniature linear guides offer several advantages: a more compact size, high running precision, quiet operation, and longer service life. Inheriting ABBA Linear Tech's base of high quality and performance, the BM series provides four key benefits:

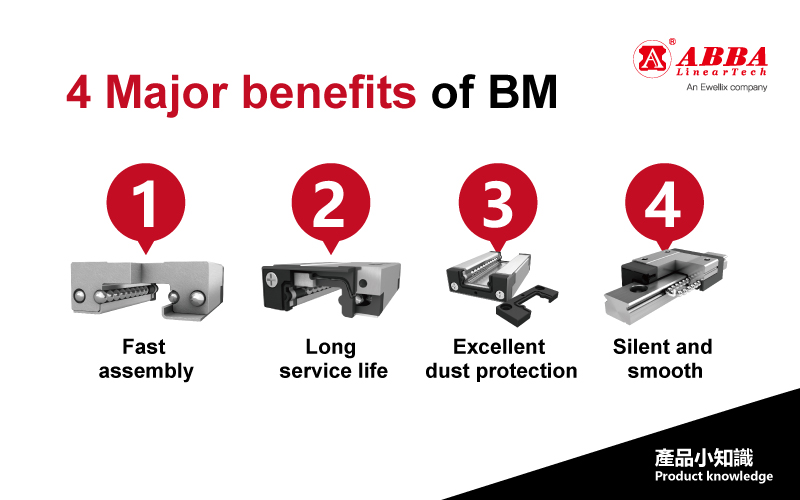

4 major advantages of ABBA BM miniature linear guides

▸ Innovative anti-drop design

The new generation ball retention system features a unique structural design that securely holds the steel balls in place, preventing them from falling out. This ensures an easy and fast assembly process without the worry of ball loss.

▸Up to 20,000 km maintenance-free

To achieve optimal maintenance-free operation, all BM blocks are factory pre-lubricated and equipped with self-lubricating oil wicks. This ensures that the grease inside the BM blocks remains in good condition, reducing friction and wear. Consequently, it maintains lubrication conditions within the system, extending the service life.

▸Excellent dustproof

Optimized seals effectively prevent dust from entering the block, providing unparalleled dust protection.

▸Silent and smooth precision running

The unique ball circulation system with a ball retention system effectively reduces friction, achieving ultra-smooth block operation and reducing noise by up to 50%. This creates a quiet and comfortable working environment, suitable for office settings, medical facilities, and laboratory applications.

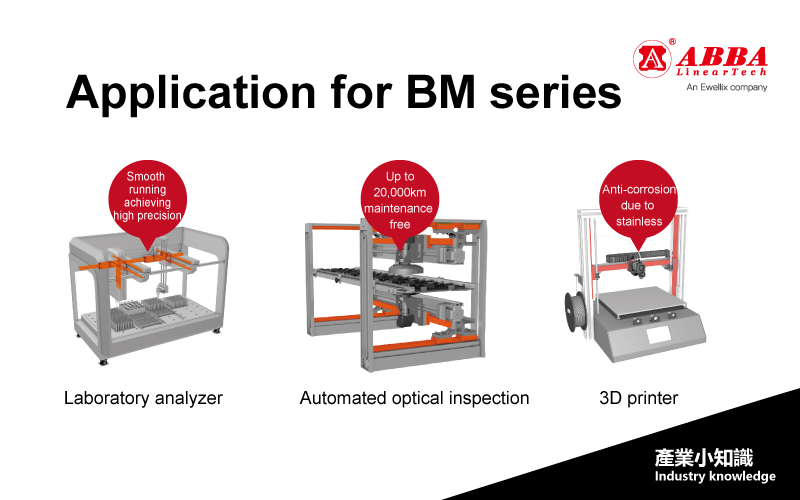

Applicaitions of BM Linear guide

BM miniature linear guides can be widely applied in precision industries such as Medical, Electronic, Semiconductor, and Optical fields, particularly excelling in the following applications:

① Laboratory equipment : In laboratory equipment such as chemical or biochemical analyzers, BM miniature linear guides enable smooth movement of probes, ensuring the accuracy and reliability of analysis results, thereby enhancing analytical efficiency.

② Automatic optical inspection equipment : In automated optical inspection equipment, BM miniature linear guides enable high-precision adjustment of dual-camera systems, with maintenance-free operation for up to 20,000 kilometers, ensuring high productivity.

③ 3D printer : During the printing process, various chemicals such as resins, metal wires, and other additives are encountered, which may corrode the rails. The stainless steel material of BM exhibits excellent corrosion resistance, capable of withstanding the corrosive effects of these chemicals, thereby extending the service life of the linear guide.

BM miniature linear guides are tailored for precision industries, perfectly aligning with market demands. Their compact design enhances equipment flexibility and efficiency within limited space, while high precision ensures stability and accuracy in operations. Exceptional durability reduces maintenance costs, and silent operation enhances comfort and productivity. The lubrication-free design promotes green manufacturing practices. BM drives space-saving and lightweight solutions for precision equipment, enabling high-speed precision and stable production.

▸Get to Know the high-speed and precision of BM Miniature Linear Guides in Just 1 Minute!