ABBA LINEAR TECH CO., LTD.

ABBA supports packaging towards automation

Packaging machinery utilizes technologies such as sensors and robots to achieve speed, accuracy, and consistency, thereby automating and simplifying packaging processes across diverse industries. These machines include filling machines, sealing machines, labeling machines, and packaging machines, offering benefits such as increased productivity, cost reduction, and protection of packaged products. Recently, integration with robots and smart control systems has significantly improved efficiency. There is also a growing emphasis on sustainable packaging, aiming to minimize material waste to the greatest extent possible.

4 Major application benefits f ABBA BR linear guides in packaging automation:

▸High load capacity

Four-row balls with a 45-degree contact angle enable a four-directional load design, capable of withstanding loads from all directions. This means mechanical components can better withstand pressure, reducing the risk of mechanical wear and damage, thus extending the equipment's lifespan.

▸Smooth running

Under the conditions of Z0/Z1 preload, the friction and vibration of the rolling elements during motion are reduced, thereby ensuring smoother operation of the linear guide. This is beneficial for enhancing the consistency and stability of product packaging."

▸Built-in self-lubrication system

The standard type of BR linear guides are equipped with a built-in self-lubrication system, eliminating the need for additional lubrication pipelines and equipment. This significantly extends the lifespan, reduces lubricating oil costs, and decreases the expenses and labor hours associated with maintenance and replacement of lubrication components.

▸High productivity at high speed

The high-speed operation of BR linear guides can accelerate the packaging process, thereby shortening the production cycle.

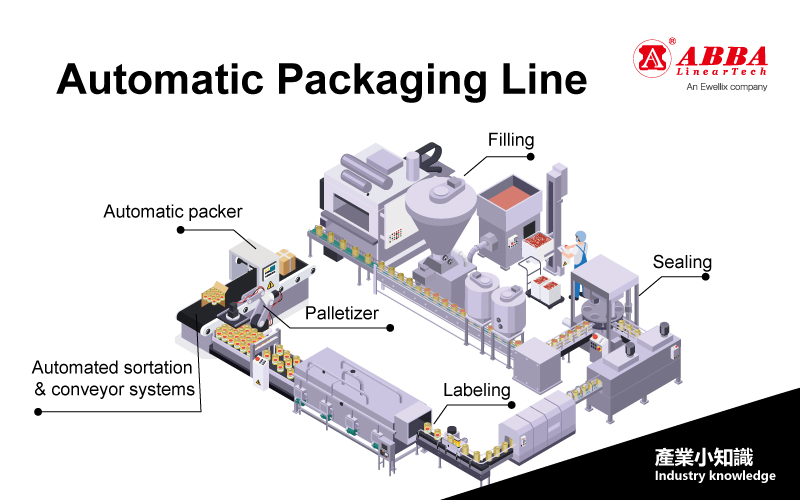

Automatic packaging line

Automatic packaging line connects packaging machines and auxiliary equipment using diversion, merging, storage, and transfer devices according to the packaging process of the product. Taking food packaging as an example, key process items include:

① Filling: Filling materials in predetermined quantities.

② Sealing: Sealing the containers

③ Labeling: Applying packaging material to cover part or all of the product's surface.

④ Automatic Conveyor: Transporting to designated areas

⑤ Sorting System: Automatically sorting according to sorting signals.

⑥ Automatic Packer: Using strapping to bundle products or packaging items.

⑦ Palletizer: Executing grabbing, handling, loading, and stacking tasks.

BR linear guides can primarily be applied to the fixture transfer of automatic packaging machines. Leveraging advantages such as stable product operation and maximized re-lubrication intervals, BR linear guides achieve high efficiency and excellent equipment performance.

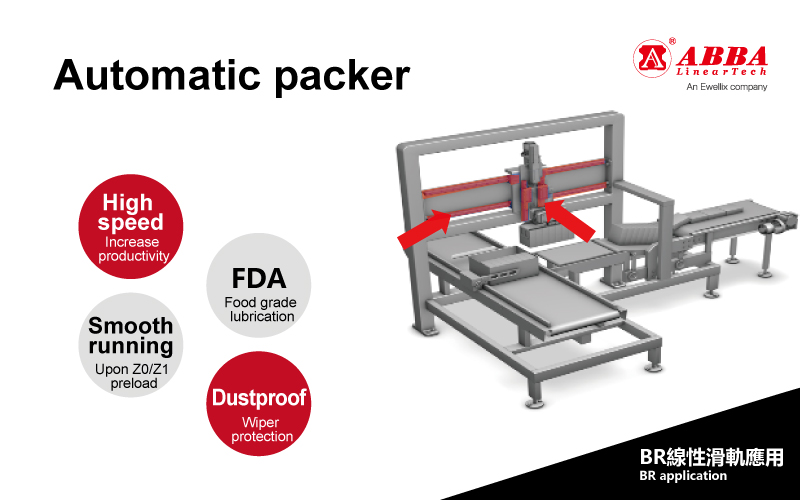

The benefits of BR linear guides in automatic packer

Thanks to the high-speed operation capability brought by BR linear guides, the high stability provided by the Z0/Z1 preload system, and the excellent dust protection offered by the scraper blades, coupled with FDA-certified food-grade lubricating oil, further ensures the safety and reliability of their application in the field of food packaging machinery.

After the COVID-19 pandemic, the rapid growth of the global e-commerce market has led to increased demand for product packaging. International attention to packaging reduction and environmentally friendly packaging has also been on the rise, with various regions introducing related regulations to address this challenge.

In such a context, BR linear guides emerge as an ideal choice for packaging machinery. They are favored not only for their high-speed operation, smoothness, and dust resistance but also for their self-lubricating properties, which offer low maintenance and low pollution advantages. This facilitates sustainable and environmentally friendly manufacturing practices. By selecting BR linear guides, not only can market demands be met, but active participation in environmental advocacy can also be achieved. This brings forth efficient solutions for plastic packaging and waste management issues, contributing to future sustainable development efforts.