ABBA LINEAR TECH CO., LTD.

ABBA BR linear guides for efficient movement, enhancing robotic system capacity.

The robot market is flourishing, driven by three main factors, including the realization of a zero-contact operation mode, the substitution of high-risk and high-load operations, and the compensation for labor shortages. According to the International Federation of Robotics (IFR) report, there were 570,000 new industrial robots globally in 2022, a yearly increase of 10.3%, with a total value of 27 billion USD. The advantages of BR linear guides, such as high speed, smooth running, and extremely low maintenance cost, are sufficient to enhance the payload capacity in robotic equipment, thereby improving equipment productivity.

ABBA BR Linear Guides offer 3 major advantages in robotic equipment:

▸High speed

High-speed motion significantly reduces the robot's moving time, assisting the materials handling quickly, executing rapid tasks, and enhancing production efficiency

▸Smooth running

The design features a high-rigidity 4-row ball arrangement in an X-shaped configuration, with a 45-degree contact angle between the balls and the raceways. This design ensures equal load-carrying capacity in all four directions, providing flexibility and effectively absorbing parallelism and height errors in multi-axis systems. It achieves smoother and more stable operation.

▸Reducing maintenance cost

The standard type of BR Linear Guides comes equipped with a self-lubrication system, eliminating the need for additional lubrication pipelines and equipment. This not only extends the service life significantly, saving lubrication oil costs, but also provides greater flexibility in the design and installation of robotic systems. It simplifies the overall system setup process, reducing both investment costs and the time required for the online deployment of robotic systems.

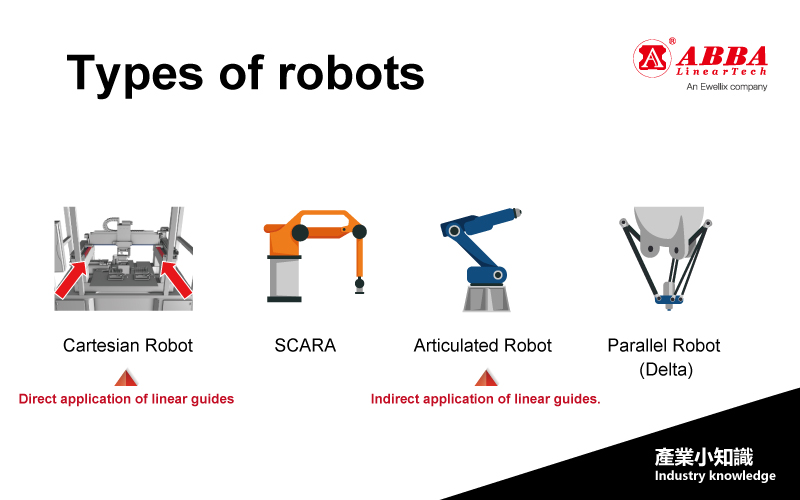

Types of robots

Robots encompass all analogs of human behavior or thought and analogs of mechanical systems resembling other living organisms (such as robotic dogs, robotic cats, etc.). According to the International Federation of Robotics (IFR) classification, robots can be broadly categorized into industrial and service robots. Industrial robots, further classified by the IFR, include Cartesian robots, SCARA, articulated robots, and parallel robots, primarily used in manufacturing industries for processes such as machining, assembly, and material handling.

Benefits of BR Linear guides in different robotic equipment applications

Among them, BR linear guides are often used in Cartesian robots and articulated robots.

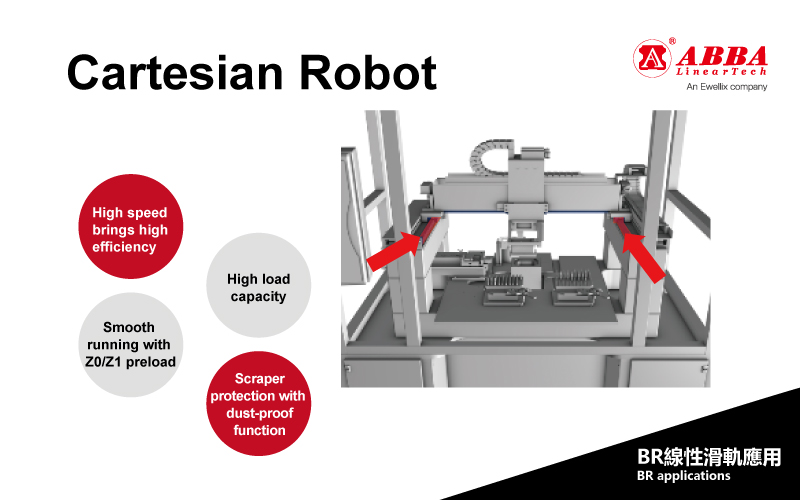

➤ Cartesian robots

▸High-speed and high-load capability.

Capable of withstanding high loads and torques, ensuring gripper devices can handle various working conditions and enhance production efficiency.

▸Smooth running

The preload system provides additional stability, ensuring smooth operation.

▸Reliable dust protection

Linear guide accessories provide reliable dust protection, reducing the risk of contamination and extending the lifespan of the equipment.

articulated robots

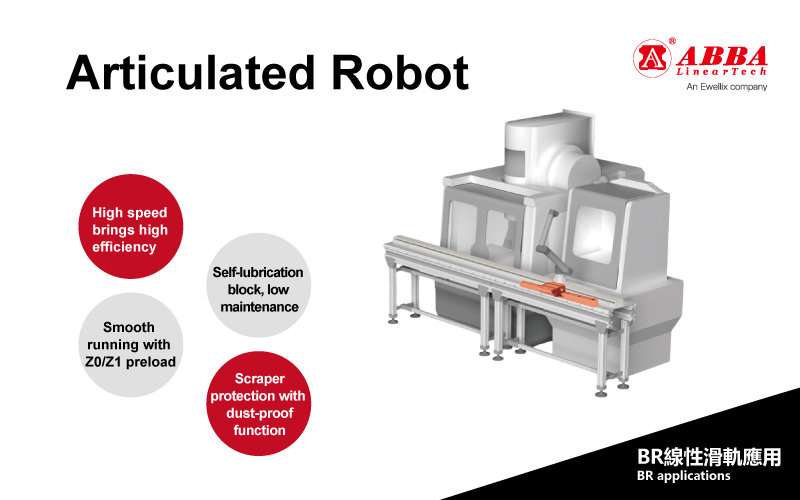

➤ Articulated robots

It has a considerable degree of freedom, suitable for tasks along any trajectory or angle. With its three-dimensional motion characteristics, it can achieve advanced non-linear movements, making it the most widely used automated mechanical device. BR linear slides are typically applied to move this equipment horizontally or vertically, and their advantages are as follows:

▸High-speed

Automated assembly requires a fast and efficient supply of components. BR provides smooth operation, ensuring the production line runs seamlessly and reducing production time.

▸Low maintenance

The self-lubricaton blocks of BR reduce maintenance frequency, minimize downtime, enhance equipment availability, and lower maintenance costs.

▸Dust protection

During the assembly automation process, it is essential to ensure the cleanliness of parts. Linear guides provide excellent dust protection, aiding in maintaining the quality and reliability of the components.

In the face of a shortage of labor, the introduction of robotic automation has become imperative for various factories. Coupled with BR linear guides, the system ensures excellent operational stability and high-precision positioning for the equipment. The self-lubrication system extends the relubrication interval, enhancing the lifespan and reducing maintenance costs. Additionally, it brings about sustainable energy-saving and environmental benefits, providing more favorable conditions for accelerating automation in the industry.